Faq's

About The Company

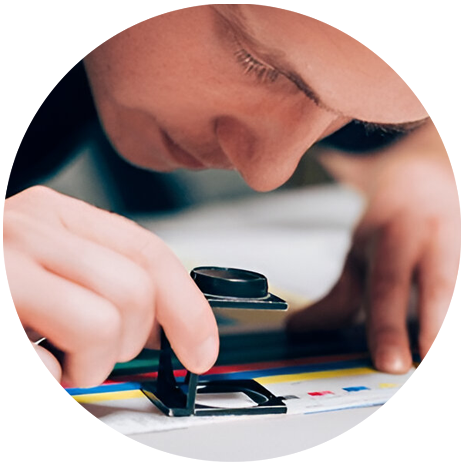

A. LABEL DESIGN & PRINTING. We are equipped with an in-house Design Studio that is peopled by graphic designers with award winning creds. Our team of Planners work in close knit exchange with the client’s marketing teams to understand and own the marcom strategies and translate them into powerful briefs that can effect the desirable visual solutions. We also co-ordinate and work with the client’s agency partners should they be in the mix. Our Printing Silo is made up of state-of-art equipment and technical staff that is design savvy.

We started out in the year 2002.

For a new job, we take 8-10 days after the approval of the creatives, receipt of payments and purchase orders. For a repeat order, we take 5-6 working days.

We recommend our clients to submit their creatives in Adobe®, Illustrator® or CorelDRAW®. The creatives could be sent to us via email or external storage devices (pen drive/hard drive).

We have no limitations in terms of the quantity of labels to be printed. We have fixed a price for the labels factoring the set up and the waste generated.

We will email a .pdf or a .jpeg file to you. We also arrange paper approval on request.

We manufacture labels in Roll and Sheet form according to the client’s requirements and preferences.

We use state-of-the-art printing technology for all our jobs. We upgrade our machinery regularly, as and when upgrades are available. Our machines are backed by the best designing and paper-related companies and professionals in the industry. We choose these so that the end product that reaches our client is of the finest quality available.

The Minimum Order Quantity of a job depends on the size of the labels. Bigger labels have smaller MOQs and vice versa. We have a fixed-lot rate. This is for the initial set up time required and the wastage created.

About Labels

The price is determined depending on the label creative. It is also based on factors such as the quantity required, size of the label, raw materials required, number of colours in the creative, fabrications required, etc.

The performance of a label is influenced by lamination, face material, varnish, adhesion, and release paper.

Letterpress technology can be used for printing on almost all kinds of surfaces including plastic, metallic films and paper. Flexographic printing is just an upgraded version of letterpress technology. It utilizes a flexible polymer plate which comes in direct contact with the label material to give it the image of the artworks.